Are electronics being recycled in Illinois? A recent project conducted by Susan Monte of the Champaign County Regional Planning Commission conducted a survey based on that question. The results are published in technical report TR-059, titled “Illinois Electronics Products Recycling Survey.”

Abstract

The survey project identified barriers to proper recycling/reuse of electronic products in Illinois counties, statewide. The recycling phone survey project was conducted December 2013 through

March 2014. Information was obtained from persons designated as county recycling coordinators, and from businesses, local governments, and agencies registered with the Illinois Environmental Protection Agency (IEPA) to collect, recycle/refurbish, or process electronic products collected in Illinois. Phone survey data was gathered regarding:

- who’s doing what in Illinois counties with regard to electronics recycling;

- who the designated recycling coordinator is for each Illinois county (and awareness of the

current IEPA annual $2,000 grant opportunity); and - types of barriers to proper recycling/reuse of electronics which may exist in Illinois

counties, with input from local government recycling coordinators, registered electronic

items collectors and recyclers.

The report includes a description of the survey design and survey population, data collection methods, and results. Observations and highlights of the survey project results are also provided in the report.

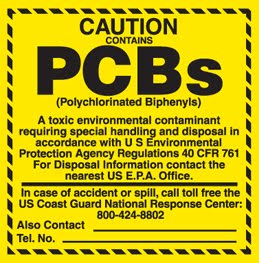

In the gaming world, a player caught cheating, using derogatory language, or other equally bad behavior will be “permabanned” or permanently banned from using the site where the bad behavior occurred. Well, that is exactly what the DeWitt count board did with PCBs (polychlorinated biphenyls) and MGP (manufactured-gas-plant) wastes. On April 23, 2015, the DeWitt county board voted to approve a settlement agreement with the owners of Clinton Landfill (near Clinton, IL) that keeps PCBs and MGP wastes out of the landfill. This ends a 7-year dispute between the landfill owners and groups opposed to PCB disposal there. Two articles from The News-Gazette sum up the happenings

In the gaming world, a player caught cheating, using derogatory language, or other equally bad behavior will be “permabanned” or permanently banned from using the site where the bad behavior occurred. Well, that is exactly what the DeWitt count board did with PCBs (polychlorinated biphenyls) and MGP (manufactured-gas-plant) wastes. On April 23, 2015, the DeWitt county board voted to approve a settlement agreement with the owners of Clinton Landfill (near Clinton, IL) that keeps PCBs and MGP wastes out of the landfill. This ends a 7-year dispute between the landfill owners and groups opposed to PCB disposal there. Two articles from The News-Gazette sum up the happenings