Ash produced from biofuel production by biomass gasification is suitable for use in bricks and concrete and lowers costs, according to a recent technical report published by ISTC.

Ash produced from biofuel production by biomass gasification is suitable for use in bricks and concrete and lowers costs, according to a recent technical report published by ISTC.

Biomass converted to biofuels grew 500 percent in the U.S. between 2002 and 2013. Biomass gasification ash (BGA) from the conversion process costs $80 a ton to landfill and ash amounts will continue to increase when the U.S. Environmental Protection Agency stabilizes agricultural markets with strong Renewable Volume Obligations under the Renewable Fuel Standard. So it is beneficial to explore utilizing BGA for useful products instead of landfilling.

Coal ash has long been effectively used as a raw material in brick and concrete production. High unburned carbon in ash adds to the firing energy of bricks in a kiln. Coal ash also has high lime content which gives it self-cementing properties that can substitute for some cement in concrete production.

Researchers at ISTC, a unit of the Prairie Research Institute at the University of Illinois at Urbana-Champaign, and Eastern Illinois University (EIU) found BGA shares these traits, allowing cheaper manufacture of standardized quality masonry products using the waste BGA.

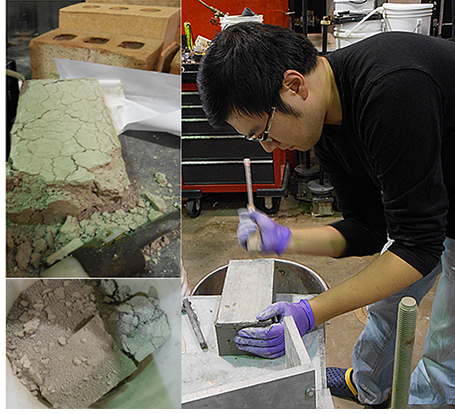

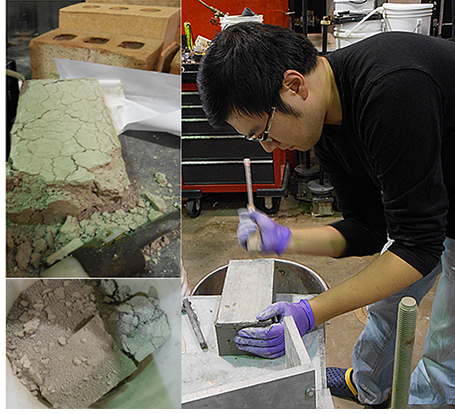

For brick making, 5-18 percent BGA replaced clay and shale. The best results were seen with ash replacement of 5-10 percent. In this range, bricks were lighter in color and weight, but still met ASTM standards for compression strength of several grades of bricks.

Concrete mixes replacing 10-20 percent of Portland cement with BGA showed minimum compressive strength typical of 3,000 psi grades. The work was conducted at ISTC labs by Vinod Patel, B.K. Sharma and Wei Zhang and at EIU labs by Peter Ping Liu and Mori Toosi. The BGA was supplied from EIU’s Renewable Energy Center.

“This offers the potential for renewable biofuel production becoming a sustainable energy source if the byproducts can be beneficially utilized avoiding costly landfills,” said Patel, a manufacturing engineer at ISTC’s Oak Brook office.

As per an economic analysis considering materials and transportation, a cement company replacing 20 percent of the 6,675 tons of cement it uses annually with BGA would save nearly $155,000. The ash producer would save an additional $107,000 by avoiding landfill fees.

“That is in addition to energy savings of 1,906 MMBTUs and reduced CO2 emissions of 1,336 tons,” explained Toosi, a Professor at the School of Technology at EIU.

In a case study for a brick producer making 120 million bricks annually, 10 percent BGA use could cut production costs by $153,000. BGA suppliers could save $2.4 million by avoiding landfilling fees.

Experimental data also suggested that ash of small particles (0.150 mm and 0.075 mm) might increase concrete strength above 4,500 psi, even at 20 percent addition of BGA.