The got-to-have feeling about the latest and greatest tech gadgets might be contributing to some major global sustainability issues. Check out what The Conversation has to say in their article, “Annual upgrade? How your mobile contract is really costing the earth.” Visit ISTC’s Sustainable Electronics Initiative website to learn more about how the environment is impacted by and social justice issue related to electronics. For specific questions related to sustainable electronics, please contact Joy Scrogum, ISTC’s Emerging Technologies Resource Specialist.

The got-to-have feeling about the latest and greatest tech gadgets might be contributing to some major global sustainability issues. Check out what The Conversation has to say in their article, “Annual upgrade? How your mobile contract is really costing the earth.” Visit ISTC’s Sustainable Electronics Initiative website to learn more about how the environment is impacted by and social justice issue related to electronics. For specific questions related to sustainable electronics, please contact Joy Scrogum, ISTC’s Emerging Technologies Resource Specialist.

Zero Waste at International Symposium

ISTC’s Zero Waste Illinois program helped make the 70th annual International Symposium on Molecular Spectroscopy a zero waste event. They symposium hosted 500+ guests this week (June 22-26, 2015) on the campus of the University of Illinois at Urbana-Champaign. ISTC made it possible for 100% of all waste from symposium break rooms to be diverted from landfill to compost. ISTC provided compost bins, liners and signage and the conferences organizers provided serving ware that can be composted. ISTC is also providing labor to collect the compost and take it to Landscaping Recycling Center in Urbana, IL.

If you are interested in hosting a zero waste event or making your office more sustainable please contact Bart Bartels. ISTC also offers free site visits to assess zero waste opportunities for businesses, manufacturing, government, and other organizations.

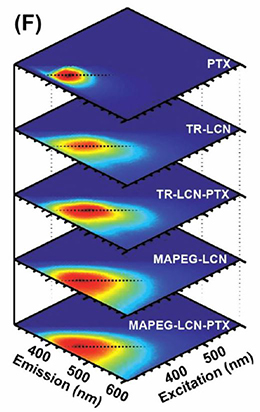

ISTC Laboratories Contribute to Biomedical Breakthrough

Labs at ISTC participated in a biomedical breakthrough by Beckman Institute faculty who developed a fast and inexpensive way to produce carbon nanoparticles. Measurements by John Scott, ISTC senior chemist, helped demonstrate that the particles can carry payloads of pharmaceutical drugs for targeted medical treatments.

Scott used one of the Center’s state-of-the-art instruments that can simultaneously measure fluorescence and absorbance of carbon nanoparticles. The work required extreme sensitivity in the parts per billion range. More on the nanoparticle breakthrough.

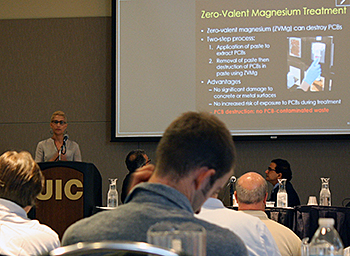

PCB Expert to Update Legacy and Emerging Issues at A&WMA Union League Club

Amanda Hughes, one of the star experts at the Prairie Research Institute’s Sept. 17 workshop on “PCBs and Their Impact in Illinois” will be the special guest speaker at the Air & Waste Management Association, Lake Michigan States Section June Environmental Breakfast on Tuesday, June 23.

Hughes, of Geosyntec Consultants, will speak on “The Longstanding and Emerging Challenges of Addressing Polychlorinated Biphenyls.” Polychlorinated biphenyls (PCBs) seemed great in their day — a set of durable synthetic molecules prized for their toughness in a variety of industrial uses. When they were found to pose human health risks they were banned, but they are still around.

From the Institute’s work, a report was published which can be downloaded HERE. Panel presentations by Dr. Hughes and others are also available for viewing at the workshop website. There is also an informative Library Guide published by the U of I Libraries HERE.

Registration is required for the 8-10 a.m. breakfast and payments ($40 ($20 students)) can be made at the organization’s website. The event is CLE and PDH credit-eligible.

New ISTC Research Report: Advanced Separation Systems for Adsorption and Filtration of Environmental Contaminants

As regulations governing environmental water pollution are enacted, the demand for improved remediation technologies and related materials must be addressed. Some of the most problematic pollutants are the volatile organic contaminants (VOCs) because of their high mobility through soils and into aquifers, and their resistance to biodegradation. Some of the most ubiquitous of these chemicals include trichloroethylene (TCE), chloroform, and methyl tert-butyl ether (MTBE) due to their prolific use in the metals finishing, dry-cleaning, water treatment and reformulated gasoline industries.

In the present study, activated carbon fiber assemblies (ACFAs) were developed and tailored to adsorb these contaminants and improve upon the current industry standard of activated carbon granules (ACGs) while remaining cost competitive. These new materials have higher surface areas, faster adsorption rates due to improved contact efficiencies, and in situ regeneration capability through electrical resistance heating when compared with ACGs.

Advantage is taken of flexible fabrication techniques to tailor porosity and surface chemistry for the specific removal of TCE, chloroform and MTBE from water. The surface area, microporosity, and surface chemistry of ACFA coatings were monitored through the use of TGA, BET N2 adsorption, elemental analysis, and XPS equipment while aqueous VOC concentrations were analyzed using a purge & trap GC. Static and dynamic adsorption evaluations displayed a major improvement over ACGs and the contaminated ACFAs also demonstrated the ability to be regenerated under relatively mild conditions.

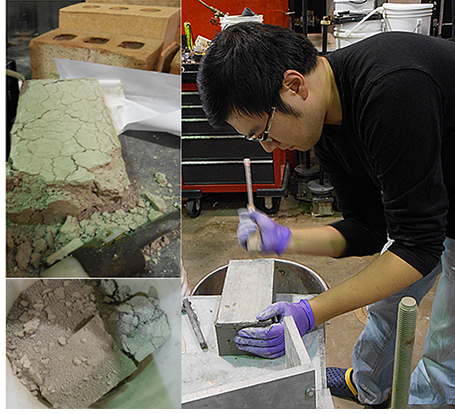

Study Finds Biomass Gasification Ash Is Right Stuff for Strong, Light Masonry

Ash produced from biofuel production by biomass gasification is suitable for use in bricks and concrete and lowers costs, according to a recent technical report published by ISTC.

Ash produced from biofuel production by biomass gasification is suitable for use in bricks and concrete and lowers costs, according to a recent technical report published by ISTC.

Biomass converted to biofuels grew 500 percent in the U.S. between 2002 and 2013. Biomass gasification ash (BGA) from the conversion process costs $80 a ton to landfill and ash amounts will continue to increase when the U.S. Environmental Protection Agency stabilizes agricultural markets with strong Renewable Volume Obligations under the Renewable Fuel Standard. So it is beneficial to explore utilizing BGA for useful products instead of landfilling.

Coal ash has long been effectively used as a raw material in brick and concrete production. High unburned carbon in ash adds to the firing energy of bricks in a kiln. Coal ash also has high lime content which gives it self-cementing properties that can substitute for some cement in concrete production.

Researchers at ISTC, a unit of the Prairie Research Institute at the University of Illinois at Urbana-Champaign, and Eastern Illinois University (EIU) found BGA shares these traits, allowing cheaper manufacture of standardized quality masonry products using the waste BGA.

For brick making, 5-18 percent BGA replaced clay and shale. The best results were seen with ash replacement of 5-10 percent. In this range, bricks were lighter in color and weight, but still met ASTM standards for compression strength of several grades of bricks.

Concrete mixes replacing 10-20 percent of Portland cement with BGA showed minimum compressive strength typical of 3,000 psi grades. The work was conducted at ISTC labs by Vinod Patel, B.K. Sharma and Wei Zhang and at EIU labs by Peter Ping Liu and Mori Toosi. The BGA was supplied from EIU’s Renewable Energy Center.

“This offers the potential for renewable biofuel production becoming a sustainable energy source if the byproducts can be beneficially utilized avoiding costly landfills,” said Patel, a manufacturing engineer at ISTC’s Oak Brook office.

As per an economic analysis considering materials and transportation, a cement company replacing 20 percent of the 6,675 tons of cement it uses annually with BGA would save nearly $155,000. The ash producer would save an additional $107,000 by avoiding landfill fees.

“That is in addition to energy savings of 1,906 MMBTUs and reduced CO2 emissions of 1,336 tons,” explained Toosi, a Professor at the School of Technology at EIU.

In a case study for a brick producer making 120 million bricks annually, 10 percent BGA use could cut production costs by $153,000. BGA suppliers could save $2.4 million by avoiding landfilling fees.

Experimental data also suggested that ash of small particles (0.150 mm and 0.075 mm) might increase concrete strength above 4,500 psi, even at 20 percent addition of BGA.

Illinois Electronics Recycling – New Technical Report

Are electronics being recycled in Illinois? A recent project conducted by Susan Monte of the Champaign County Regional Planning Commission conducted a survey based on that question. The results are published in technical report TR-059, titled “Illinois Electronics Products Recycling Survey.”

Abstract

The survey project identified barriers to proper recycling/reuse of electronic products in Illinois counties, statewide. The recycling phone survey project was conducted December 2013 through

March 2014. Information was obtained from persons designated as county recycling coordinators, and from businesses, local governments, and agencies registered with the Illinois Environmental Protection Agency (IEPA) to collect, recycle/refurbish, or process electronic products collected in Illinois. Phone survey data was gathered regarding:

- who’s doing what in Illinois counties with regard to electronics recycling;

- who the designated recycling coordinator is for each Illinois county (and awareness of the

current IEPA annual $2,000 grant opportunity); and - types of barriers to proper recycling/reuse of electronics which may exist in Illinois

counties, with input from local government recycling coordinators, registered electronic

items collectors and recyclers.

The report includes a description of the survey design and survey population, data collection methods, and results. Observations and highlights of the survey project results are also provided in the report.

The Army is Greenest in Workplace Sustainability

The U.S. Army Corps of Engineers’ Construction Engineering Research Laboratories in Champaign was the 2015 champion for green workplace achievements. It and nine other winners of the first Illinois Green Office Challenge were announced Thursday. Find out about all the winners here.

PAHs in IL River Sediment – New Technical Report

From where could the polycyclic aromatic hydrocarbons (PAHs) in the Illinois River sediments have come? Researchers from the University of Illinois at Chicago with a grant from the Hazardous Waste Research Fund investigated possible sources. The details of their research is in the newly published technical report Tr-058, titled “Source Apportionment of Polycyclic Aromatic

Hydrocarbons in Illinois River Sediment.”

ABSTRACT

The accumulation of over six million metric tons of sediment annually in the Illinois River Valley degrades its recreational, commercial, and ecological value. This necessitates dredging a large volume of sediment to restore water depth and makes beneficial reuse of the sediment a priority. Unfortunately, many reuse applications are limited by contamination from polycyclic aromatic hydrocarbons (PAHs), particularly benzo(a)pyrene in the sediments. Existing contaminant standards do not consider whether the sources of PAHs are from current petroleum combustionbased inputs or whether they represent “legacy pollution” such as coal dust released from barges, trucks, and storage. The latter is typically found in black carbon form that might be less bioavailable, and thus may not represent as high a risk for beneficial reuse. A source apportionment (SA) analysis was undertaken to identify the sources of PAHs to the Illinois River and to determine if they come from these potentially low bioavailable forms.

Priority PAHs were analyzed in 80 sediment cores sampled from Illinois River pools and backwater lakes between Hennepin, Illinois and the Peoria Lock and Dam. PAH diagnostic ratio analysis and a Positive Matrix Factorization (PMF) multivariate receptor model were used to characterize the PAH dataset, identify specific sources of pollutants, and quantify source contributions to the river sediment. Predicted sources from the SA analysis were identified using a database of compiled reference PAH profiles for coal dust, coal tar sealcoat, motor oils, biosolids, as well as fossil fuel combustion residues from gasoline and diesel engines, power plants, and coke production.

Three sources (S1, S2, and S3) were required to reconstruct most of the variation in the Illinois River contaminant dataset by PMF source apportionment. PMF results suggested that a mixed upland source and coal-derived sources including coal tar sealcoat (S1 and S2, 75%) were major contributors to sediment PAHs in the Illinois River, as well as a diffuse traffic-based source (S3, 25%). Liquid petroleum was not identified as a signficant source of PAHs to Illinois River sediment. Coal dust was not uniquely resolved from the coal-derived sources and thus could not be assessed for reduced PAH bioavailability. Finally, comparison of PMF results with those from the widely-used PAH diagnostic ratio method indicated that the latter does a relatively poor job of uniquely resolving PAH sources in the sediments.

ISTC publishes Billion Gallon Water Challenge updates

As population increases, the demand for clean, fresh water will also rise, making existing supplies a very precious resource in Illinois and other parts of the US. ISTC seeks to help businesses, industries, communities, and the general public with water conservation measures such as:

- Using water more efficiently

- Reuse of water

- Finding new ways to keep our water resources as clean as possible

ISTC has set a goal of conserving one billion gallons of water in Illinois. It is funding projects and conducting its own research along with other scientists, industry and other experts that will be looking for:

- Improved treatment of wastewater

- Reuse of process water in factories

- Novel recycling methods

- Other significant water-saving measures

To date, there have been three case studies published as a result of these efforts. They are:

- Carus Water Conservation Case Study

- Acoustic Monitoring Case Study

- University Water Conservation Program Case Study

For more information, visit the One Billion Gallon Water Challenge web site.