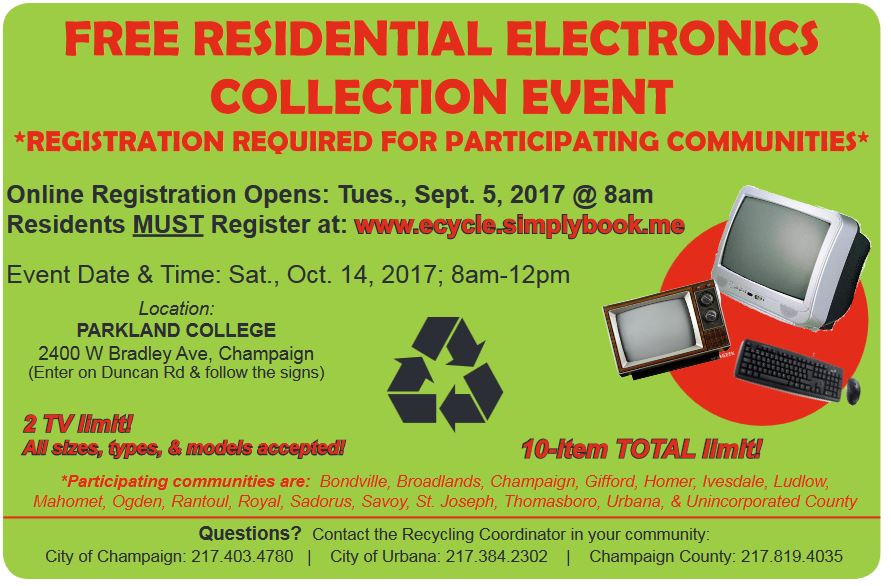

The Commission for Environmental Cooperation (CEC), an intergovernmental organization supporting cooperation among NAFTA partners to address environmental issues of continental concern, has published a new white paper focused on food waste in North America.

Characterization and Management of Food Loss and Waste in North America provides statistics about the amount of food lost or wasted collectively, and by country, examines root causes and the environmental and economic impacts. It also summarizes current approaches and opportunities to reduce food loss and waste in the US, Canada, and Mexico. This white paper presents an overview of the accompanying foundational report, and serves as a key resource for policy makers at all levels of government, as well as members of the food industry.

Characterization and Management of Food Loss and Waste in North America provides statistics about the amount of food lost or wasted collectively, and by country, examines root causes and the environmental and economic impacts. It also summarizes current approaches and opportunities to reduce food loss and waste in the US, Canada, and Mexico. This white paper presents an overview of the accompanying foundational report, and serves as a key resource for policy makers at all levels of government, as well as members of the food industry.

Some highlights from the Key Findings section include:

“Approximately 168 million tonnes of FLW are generated in North America each year. This estimate encompasses all stages of the food supply chain, including the pre-harvest and consumer stages. Per country, this equates to 13 million tonnes in Canada, 28 million tonnes in Mexico and 126 million tonnes in the United States…When including all stages of the food supply chain, per-capita FLW in Canada is comparable to that in the United States (396 kilograms/person/year and 415 kilograms/person/year, respectively). The per-capita FLW generation in Mexico is much lower—at 249 kilograms/person/year. Nevertheless, when excluding pre-harvest and consumer stages, rates across all three countries are comparable: 110 kilograms/person/year for Canada and the United States, and 129 kilograms/person/year in Mexico.”

“Causes of FLW across the food supply chain include:

• overproduction by processors, wholesalers and retailers;

• product damage;

• lack of cold-chain infrastructure (refrigeration during transportation and storage);

• rigid food-grading specifications;

• varying customer demand; and

• market fluctuations.”

Among the many listed environmental and economic impacts, is the fact that market value of the food loss and waste in North America per year is US $278 billion.

The CEC has also produced an infographic which summarizes the various key findings and suggested approaches to reduce food loss and waste. See http://www.cec.org/sites/default/fwinteractive/index-en.html.

Addressing the issues of food loss and waste regionally and nationally will help the global community to make progress toward the following UN Sustainable Development Goals (SDGs):

- SDG 12: Ensure sustainable consumption and production patterns. Specifically, Target 12.3, “By 2030, halve per capita global food waste at the retail and consumer levels and reduce food losses along production and supply chains, including post-harvest losses.” In alignment with SDG Target 12.3, in 2015 the US EPA and USDA jointly announced the nation’s first domestic goal to reduce food loss and waste by half by the year 2030.

- SDG2: End hunger, achieve food security and improved nutrition and promote sustainable agriculture. The key findings of the CEC white paper, for example, include the amount of food loss and waste for North America per year is equivalent to 217 trillion kilocalories in potential energy. Feeding America reports that 41 million people in the US struggle with hunger, and food insecurity exists in every county in America.

- SDG 13: Take urgent action to combat climate change and its impacts. Not only does discarded food contribute to greenhouse gas emissions, but consider the energy use and emissions associated with the production of food that goes uneaten. Reducing inefficiencies throughout the food production and consumption system can help avoid emissions that our warming world cannot afford (for one discussion of this, see the April 7, 2016 issue of the Guardian).

What can you as an individual do? First, become familiar with the sources of food loss and waste and suggested approaches, as outlined in the CEC white paper and other resources highlighted on this blog in the “food waste” category. Let your legislators, and favorite retailers, restaurants, food service operations, and manufacturers of food products know that you appreciate any positive efforts they take to address food waste, and that you expect improvement aligned with strategies identified by CEC and other organizations focused on this issue. Check out the US EPA suggestions for reducing food waste at home, and further their Call to Action by Stakeholders. Also, check out the Save the Food web site produced by the Natural Resources Defense Council and the Ad Council. The Love Food Hate Waste web site produced by UK organization WRAP also provides a wealth of tips and even recipes to help ensure food fills stomachs and not landfills. And finally, as you learn more about food waste issues and strategies for reduction, share what you learn and the stories of the actions you’re taking with others. A problem of this complexity and magnitude requires everyone to contribute to the solution. Your sharing knowledge and inspiration is crucial.

The Ewoks’ Forest Moon of Endor sustained them in their happy lifestyle. But what happened on Tatooine, where Anakin and Luke grew up? Environmentally it took a wrong turn at some point, reminding us of droughts and wildfires growing more common in California and across the country.

The Ewoks’ Forest Moon of Endor sustained them in their happy lifestyle. But what happened on Tatooine, where Anakin and Luke grew up? Environmentally it took a wrong turn at some point, reminding us of droughts and wildfires growing more common in California and across the country.