The debate continues: how much risk to human health is the transfer of pharmaceuticals and personal care products (PPCPs) through soils to food plants when biosolids, sewage effluents, and animal wastes are applied to fields? As scientists speculate and study the factors that affect risk, researchers at the Illinois Sustainable Technology Center (ISTC) are finding innovative solutions to remove PPCPs before they contaminate the vegetables and fruits we consume.

PPCPs are the chemicals that make up fragrances, cosmetics, over-the-counter drugs, and veterinary medicines. These chemical residues in the environments are considered emerging contaminants because they are not yet regulated by state and federal agencies.

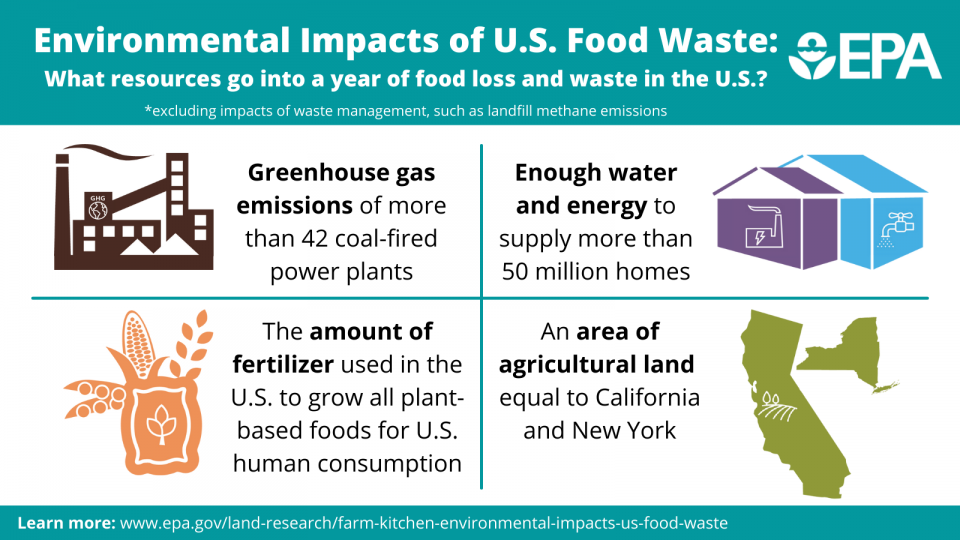

Organic wastes like biosolids, sewage effluent, and animal waste contain PPCP residues. When these are applied to farm fields, some of the chemicals may degrade, while others may transfer from soils to roots of vegetables and fruits, and then possibly accumulate in edible plant tissues.

Field studies have shown that pharmaceutical concentrations in soils were lower than predicted because PPCPs may degrade in soils, latch on to soil particles, or run off/leach into surface and groundwater. Yet continued and long-term application of PPCP-containing biosolids, animal wastes, and wastewater effluents may increase their concentration levels in plants, according to Wei Zheng, ISTC scientist.

“There has been much argument and debate if PPCPs derived from organic waste application in crop fields can cause risks on public health,” Zheng said. “This issue will become even more at the forefront as the use of biosolids and sewage effluents in crop production systems increases. More studies are necessary because PPCPs vary in their toxicity and physicochemical properties in the environment. In particular, the compounds that are highly persistent and toxic will be a concern.”

Zheng reviewed the literature, summarized the research findings, and made recommendations for future research in a recent article published in Current Pollution Reports.

Factors affecting PPCP transfer

In his review, Zheng reiterated that the factors that have the greatest effect on PPCP transfer are the properties of the PPCPs and soils as well as plant species. Plants grown in sandy soils have higher levels of PPCPs than those grown in high organic matter and clay soils. For certain PPCPs that are destroyed in soils, the process breaks down the original compound into metabolites that may be more toxic and mobile. Metabolites with lower molecular weights could be taken up by plant roots more readily.

Studies have also found that leafy vegetables, such as lettuce and cabbage, tend to have a higher potential to take in PPCPs than root vegetables. Furthermore, certain chemicals accumulate in the roots and have little effect on human health, while others can be transferred to leaves. Further research is needed to develop thresholds for accumulations of PPCPs in food crops when biosolids, effluents, and animal manure are used on fields.

Mitigation efforts

At ISTC, Wei and colleagues are studying several technologies to remove PPCPs, either before they reach the soils or after sewage waste application. The study is being supported by a project funded by the U.S. Department of Agriculture (USDA).

In the project, Wei is studying the feasibility of using inexpensive oils to capture hydrophobic PPCPs from wastewater effluents. The treatment, which would be used at water treatment plants, is especially low cost when applying used cooking oils, such as those from restaurants.

One advantage of this process is that oils remove PPCPs from rural sewage water while leaving behind the nutrients that fertilize crops. After capturing PPCPs, the spent oils can be used as fuel for diesel engines. The process can eliminate the captured contaminants.

Carbon-rich biochar produced from forest and agricultural residues can be used as a filter to absorb PPCPs from sewage water. Biochar can also be directly applied to soils.

Studies found that the average PPCP concentrations in lettuce leaves decreased by 23 to 55 percent when biochar was used in the soil compared with the soils without biochar. Biochar can also be composted with solid waste to immobilize PPCPs and reduce their transfer in soil-plant systems.

In the USDA project, scientists will conduct laboratory, field, and numerical modeling studies to better understand the transfer of PPCPs to crops when rural sewage effluents are applied to agricultural lands. The results will help federal and state agencies and farmers evaluate their current nutrient management and nontraditional water-use practices, inform science-based regulatory programs, and suggest best management strategies to minimize risks and promote the safe and beneficial use of nontraditional water in agriculture.

Media contact: Wei Zheng, 217-333-7276, weizheng@illinois.edu

news@prairie.illinois.edu

This story originally appeared on the PRI News Blog. Read the original story.