A newly developed system in the lab could become a boon for farmers in the field. Illinois Sustainable Technology Center (ISTC) scientist Wei Zheng and colleagues are creating a designer carbon-based biochar that captures phosphorus from tile drain runoff water and recycles it in soils to improve crop growth.

Zheng hypothesizes that this is a win-win strategy that will lead to increased crop yields and less nutrient runoff into water from agricultural fields.

Fertilizer phosphorus applied for plant growth tends to dissolve and leach out through field tile lines, so it promotes algae growth in nearby waterways. Harmful algal blooms (HAB) appear in lakes in the summer and die off once the growing season ends, contributing to oxygen-depleted waters, which result in fish kills and other adverse effects on aquatic life.

The yearly HAB prompted development of Illinois’ Nutrient Loss Reduction Strategy, which aims to reduce phosphorus in Illinois waters by 25 percent by 2025.

A sustainable, novel approach

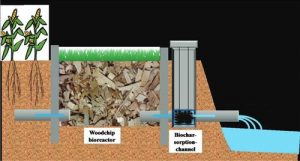

Zheng and his colleagues at the University of Illinois (U of I), the Illinois Farm Bureau, and other groups believe their strategy will address this problem. By installing a bioreactor in the field with a biochar-sorption filter, water that runs through the tile system is filtered to remove nutrients before it reaches lakes and streams.

The filter holds biochar—a biomass product that looks like charcoal and is made mostly of carbon with high calcium and magnesium—which traps fertilizer nutrients. The biomass is made into small pellets that won’t block water flow.

The filter holds biochar—a biomass product that looks like charcoal and is made mostly of carbon with high calcium and magnesium—which traps fertilizer nutrients. The biomass is made into small pellets that won’t block water flow.

In the lab, Zheng is studying different types of designer biochars made from sawdust, grasses, or crop residue pretreated with lime sludge, for example, to find the one that is the most effective in capturing phosphorus.

“We have generated some designer biochars that have extremely high capacities for holding dissolved phosphorus,” Zheng said. “Our previous studies have shown that biochar can not only strongly adsorb nutrients such as phosphorus, but also has a high sorption capacity for other contaminants, such as pesticides and antibiotics.”

This year, Zheng and his collaborators will scale up their technology to develop a bioreactor and biochar-sorption-channel system for a field trial on a commercial farm in Fulton County. In the second year of the project, the team will establish a bioreactor system that is able to treat drainage water received from a 12-acre field. Water testing will confirm how successful the system is at reducing phosphorous runoff.

An additional part of the project, also slated for next year, is to remove biochar pellets from the channel after fertilizer season and apply the phosphorus-captured biochars to the fields where they will slowly release phosphorus and other nutrients into the soil. As a result, producers can keep fertilizer costs down and increase crop yields when applying the biochar pellets at optimal times in the growing season.

“The goal in adopting this technique is to keep applied phosphorus in the agricultural loop and prevent it from leaching into waterways,” Zheng said.

Benefits of a research team-organization collaboration

Illinois Farm Bureau is involved in this project at the state and Fulton County level to foster interactions between farmers and U of I researchers. Their participation helps to ensure that the research is focused on applicable, realistic practices for Illinois farmers, according to Lauren Lurkins of the Illinois Farm Bureau.

The Farm Bureau helps identify producers who are willing to participate in research and in funding and outreach opportunities, such as field days.

“Research including Wei’s can help to add practices to or update the science behind existing practices in the Nutrient Loss Reduction Strategy,” Lurkins said. “PRI has a lot of researchers and resources that our farmers utilize. They cover everything from groundwater for rural area consumption to weather monitoring, which are all important to agriculture.”

Results from the project are expected in 2023. It is funded by the Illinois Nutrient Research & Education Council.

In late 2019, Zheng was appointed Vice Leader of the American Society of Agronomy’s Biochar Committee for his research in various projects on biochar. Several project descriptions are available, including: Using Biochar as a Soil Amendment for Sustainable Agriculture, Sorption Properties of Greenwaste Biochar for Two Triazine Pesticides, and Carbon Sequestration Using Biochar.

——-

Media contacts: Wei Zheng, 217-333-7276, weizheng@illinois.edu; Lauren Lurkins, llurkins@ilfb.org; Prairie Research Institute Communications Team, news@prairie.illinois.edu

With the start of a new year, ISTC’s Institutional Water Treatment (IWT) program is offering a new service to test water sources for Legionella, the bacterium that causes Legionnaires’ disease, to decrease exposure for clients with weak immune systems.

With the start of a new year, ISTC’s Institutional Water Treatment (IWT) program is offering a new service to test water sources for Legionella, the bacterium that causes Legionnaires’ disease, to decrease exposure for clients with weak immune systems.