Although plastics have led to many positive innovations that have benefitted human society (e.g. less expensive medical devices, more portable electronic devices, increased fuel efficiency of vehicles made with plastic incorporated in their bodies, etc.), it is clear that plastic pollution is an ever-growing problem that threatens human and environmental health. When considering the fate of all plastic ever produced, Geyer et al. estimated that as of 2015, “approximately 6300 Mt of plastic waste had been generated, around 9% of which had been recycled, 12% was incinerated, and 79% was accumulated in landfills or the natural environment. If current production and waste management trends continue, roughly 12,000 Mt of plastic waste will be in landfills or in the natural environment by 2050.” [Note: Mt=million metric tons] In its 2022 report, Global Plastics Outlook: Economic Drivers, Environmental Impacts and Policy Options, the Organisation for Economic Co-operation and Development (OECD) stated that “Widespread plastics use and inadequate prevention measures have led to persistent plastic leakage. In 2019 an estimated 22 Mt of plastics leaked into the environment. The largest leakage source (82%) is mismanaged waste, i.e. waste that is inadequately disposed of. Other sources are abrasion and losses of microplastics (12%), littering (5%) and marine activities (1%).” They define “mismanaged waste” as “Waste that is not captured by any state-of-the-art waste collection or treatment facilities. It includes waste that is burned in open pits, dumped into seas or open waters, or disposed of in unsanitary landfills and dumpsites.” Even when plastics are collected and processed at a recycling facility, there is still potential for pollution. A study published this month in the Journal of Hazardous Materials Advances describes the analysis of wastewater from a UK plastics recycling facility before and after filters were installed. While filters decreased the discharge of microplastics, even with the filters in place, the total discharge from the multiple washes used in processing could produce up to 75 billion particles per cubic meter of wastewater. If these findings are extrapolated across the whole of the plastics recycling industry, the potential pollution from plastic recycling facilities alone is mind-boggling.

Plastics in the environment break down into smaller and smaller pieces over time. The full extent of the impacts of micro- and nano-plastics on Earth’s ecosystems is unknown, but we do know that wildlife may ingest plastic accidentally when eating food waste contained in plastic, because of visual similarities of plastics to their food sources, and in some cases because the plastic smells like food. When prey animals consume plastic, their predators ingest the plastic along with the prey. Even humans can ingest plastic in this way, and microplastics can also be inhaled. Microplastics are found worldwide, even in protected areas. They have been found in sea ice in the Arctic and on the ocean floor. They’ve even been found in human breast milk.

Given the scale and ubiquity of plastic pollution, in April 2023 the U.S. Environmental Protection Agency (EPA) released a Draft National Strategy to Prevent Plastic Pollution. This builds upon EPA’s National Recycling Strategy, focusing on means to reduce, reuse, collect, and capture plastic waste.

EPA has identified three key objectives for the strategy. The draft strategy document lists proposed actions associated with each objective.

EPA has identified three key objectives for the strategy. The draft strategy document lists proposed actions associated with each objective.

- Objective A: Reduce pollution during plastic production. This entails designing products for reuse and recycling, using less impactful materials, phasing out unnecessary products, and ensuring proper controls at plastic production facilities.

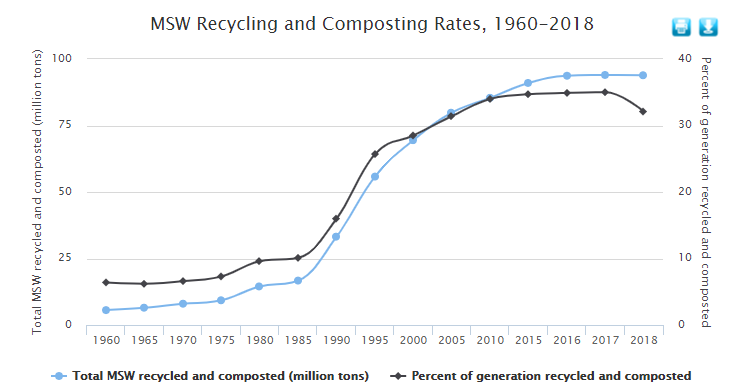

- Objective B: Improve post-use materials management. This involves the pursuit of circularity through pathways susch as reuse, refilling, and composting.

- Objective C: Prevent trash and micro/nanoplastics from entering waterways and remove escaped trash from the environment. The pursuit of this objective may involve policy, programs, technical assistance, compliance assurance efforts, improved water management, improved measurement, increased public awareness, and further research.

Read the full draft strategy at https://www.epa.gov/system/files/documents/2023-04/Draft_National_Strategy_to_Prevent_Plastic_Pollution.pdf. An executive summary is also available.

EPA has opened a public comment period on this draft national strategy. Comments are due on or before June 16, 2023. EPA is asking the public to consider several key questions when reviewing and commenting on the draft strategy. To see these questions and learn more about how to submit your comments, see https://www.epa.gov/circulareconomy/draft-national-strategy-prevent-plastic-pollution#feedback.