Whichever winter holiday(s) you observe, odds are ‘tis the season for gift giving. Even if you don’t observe any of the major winter holidays, you’ll surely think about gifts at some point in the near future to celebrate a special occasion. If you’d like to align your gifts with sustainable values, the following ideas and resources might be helpful. Please note that links and companies mentioned in this post are for informational purposes only, and should not be construed as endorsements by ISTC, the Prairie Research Institute, or the University of Illinois.

Give an Experience

Many of us are fortunate enough to have plenty of “stuff” already, and if that’s the case for your intended recipient, consider an alternative to giving them more material goods. Experiences can often be more meaningful and personalized than physical gifts and presenting them can be an opportunity to start a conversation about consumption and its impacts on resource use, though one should not equate gifting experiences with avoiding consumption. Experiences still involve the use of material goods and consumption of resources; e.g., cooking someone their favorite dinner still requires the use of cookware, energy, and ingredients that themselves require natural resources to grow, raise, or manufacture. However, some gifted experiences may use items or resources that you or your recipient already own or would consume regardless of the special occasion. Continuing the previous example, you’re not likely to buy new pots or appliances to cook dinner, and since your recipient would need to eat anyway, there would always be impacts associated with the ingredients for the meal. Of course, other experiences may involve situations outside normal day-to-day circumstances that necessitate the use of resources (e.g., fuel for travel) we would not otherwise consume. Taking a spouse on a dream vacation or treating your best friend to a concert performance by their favorite band are examples. In such instances, it’s important to remember that giving an experience is less about avoiding resource use than shifting human attitudes and focus. The goal when gifting an experience is not to completely avoid consumption–we all consume resources as part of being alive. Rather, giving an experience shifts the focus away from material items as ends in themselves toward human interactions and the associated memories that will endure longer than most physical gifts possibly could. Memories are durable gifts! As a person who cares about sustainability, you can still try to incorporate responsible consumption into the equation if possible—perhaps by using local, sustainably harvested ingredients for the special dinner you’re preparing, buying carbon off-sets for the travel to that dream destination, or taking public transportation to the concert. The key is sharing or fostering experiences fulfills the human need for authentic connection rather than human desires for material goods, and reinforces the idea that relationships matter more than stuff. Valuing relationships between living things (in this case between people) is essential to thinking about ecosystems and the mindset that humans are a part of, rather than apart from, the rest of the natural world. Valuing relationships/connections can build a foundation for more sustainable behavior.

Give to Charity

Another option is to make a donation in honor of your loved one to a charitable organization that resonates with their interests and values. If you aren’t already aware of a specific group dear to their heart, you can search Charity Navigator at https://www.charitynavigator.org/ to find organizations by cause. The results display ratings, if Charity Navigator has adequate information to calculate one, based on “the cost-effectiveness and overall health of a charity’s programs, including measures of stability, efficiency, and sustainability.” You can filter the results by ratings, different aspects of performance (called “Beacons” on the site), state, organization size, and other factors. For example, I entered the term “sustainability” into the site’s search bar with the state filter “IL.” Charity Navigator also produces curated lists of charities, including “Where to Give Now,” “Popular Charities,” and “Best Charities.” As examples, check out the List of Best Women’s Charities, the “Where to Give Now” list for the Hawaii Wildfires, the List of Most Popular Charities. You can of course always enter keywords into Google or another search engine, but you might appreciate having Charity Navigator do some of the virtual “leg work” for you and having their expert analysis.

Note that your donation need not be monetary—you could donate your time or skills through volunteering. You might use your social media experience to help with promotion and online engagement for the literacy program for which your wife works, for example. You might even combine supporting a good cause important to your loved one with gifting an experience. For example, you might arrange to volunteer with an animal-loving friend at the local Humane Society shelter or pick up litter with your dad at his favorite nature preserve.

Give Gifts that Foster Reuse and Waste Reduction

Maybe you want to give your favorite waste reduction wonk items to help them get closer to the ideal of zero generation, but all you can think of are reusable coffee cups and cloth grocery bags which you know they already own. Here are some ideas and lists from which to draw inspiration.

- New York Magazine’s the Strategist “The Very Best Compost Bins”

- Sustainable Jungle’s 13 Plastic-Free Food Storage Containers Making You The Envy Of The Lunchroom

- Cincinnati Recycling and Reuse Hub’s Sustainable Self-Care: Low Waste Personal Hygiene Products

- iFixit’s How to Give Repairable Gifts

- Modern Mending’s Gift Ideas to with clothing repair. For those without sewing savvy, check out https://nosopatches.com/.

Give Gifts that Reduce Dependence on Fossil Fuels

Friends don’t let friends rack up avoidable greenhouse gas emissions. Consult the following guides for some quick tips.

- Consumer Reports 5 Green Reasons to Choose Battery-Powered Lawn Tools. Written by Paul Hope, this includes a list of “5 Standout” examples.

- Time Magazine’s Holiday Gifts That Actually Fight Climate Change

- For people in the Champaign-Urbana area, where ISTC headquarters is located, check out Fares & Passes info from CU MTD. Elsewhere in IL, check out the Illinois Public Transportation Providers Map to identify local resources.

Give Gifts Free of PFAS

According to PFAS Central, a project of the Green Science Policy Institute, “PFAS, sometimes referred to as PFCs or highly fluorinated chemicals, are used in many consumer products and industrial applications because of their oil-, stain-, and water-repellent properties. Examples of chemicals in this class include PFOA, PFOS, and more than 3000 related compounds. The most studied of these substances is a chemical called PFOA, which is linked to kidney and testicular cancer, elevated cholesterol, decreased fertility, and thyroid problems and decreased immune response to vaccines in children. The most studied of these substances is a chemical called PFOA, which is linked to kidney and testicular cancer, elevated cholesterol, decreased fertility, and thyroid problems and decreased immune response to vaccines in children.” PFAS persist in the environment and pollute even the most remote places. Check out ISTC’s information and work on PFAS. This recent video from Bloomberg tells the fascinating story of how one woman uncovered how PFAS pollution became prevalent in her area.

So, these substances are clearly bad news for human and environmental health, but they’re in lots of consumer products—how can you help friends and family avoid exposure? Check out https://pfascentral.org/pfas-free-products/ for a list of PFAS-free outdoor gear, apparel, shoes, personal care products, baby gear, furniture, food ware, carpets and rugs, textiles, and home maintenance products.

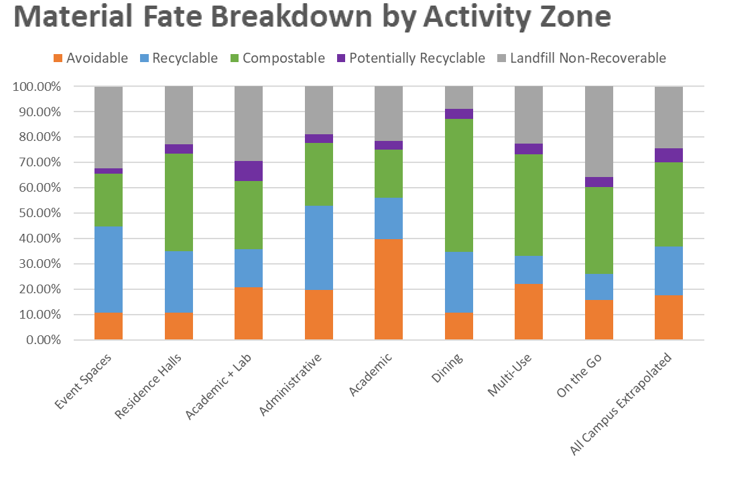

The

The  material categories.

material categories.