It is challenging to integrate renewable resources into the distribution grid of fossil-fueled power plants when energy is most needed. The results are often intermittent and unpredictable, which makes it difficult to match energy demand with supply.

In three new U.S. Department of Energy (DOE)-funded projects, scientists in the Prairie Research Institute will design systems and explore the feasibility of combining the use of renewable and fossil energy sources to ensure both short and long-term reliability in electric power delivery.

A natural gas energy storage system

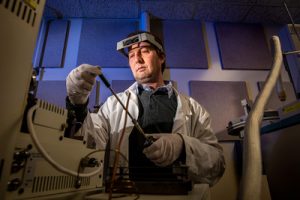

In a three-year project, scientists at the Illinois Sustainable Technology Center (ISTC) will design a 10 MWh compressed natural gas energy storage (CNGES) system at the University of Illinois’ Abbott Power Plant, which uses oil and coal to power campus.

Electrically powered compressors are used in CNGES to raise the pressure of natural gas during off-peak hours. Natural gas is then stored in cylinders or in an underground pipeline.

During peak-demand hours, the stored gas is discharged through an expander-generator to partially recover the electricity used in the compression step. The chemical energy stored in the natural gas is integrated with fossil fuels to provide peak power using existing compressors and pipelines.

“The project, which will demonstrate the benefits to the power plant, energy grid, and the environment, will advance the CNGES technology towards commercial use,” said Kevin OBrien, who is principal investigator for this project and leads ISTC. Some of the benefits include reduced fuel costs, carbon emissions, and maintenance. It also increases plant efficiency.

The CNGES technology has not yet been tested with fossil fuels. Once the project is complete, findings will aid in understanding the advantages and challenges of integrating energy storage with coal and natural gas fired power plants.

DOE awarded $200,000 for the $250,000 project. The co-principal investigator is Mohamed Attalla, executive director of the U of I Facilities and Services.

Compressed air storage

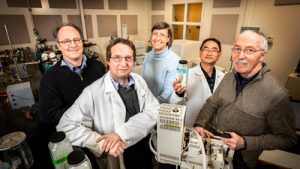

A team of geologists at the Illinois State Geological Survey (ISGS), along with engineers and power plant specialists, are designing a compressed air energy storage system that will increase the reliability of renewable energy from solar and wind farms and integrate the system with the Abbott fossil fuel power plant. DOE awarded $200,000 for the project, with a total budget of more than $250,000.

Compressed air energy storage (CAES) is a technology used to store compressed air in the subsurface sedimentary strata so that when the high-pressure air is returned to the surface it powers turbines to produce additional electricity as needed during power interruptions from severe weather or fossil fuel disruptions. The team plans to design an integrated system to store compressed air and thermal heat generated by compression underground.

Part of the project will involve evaluating the capability of sandstone aquifers to quickly release air to run turbine generators and determining the equipment needed to remove residual saline water to avoid corrosion in the system. The team will also quantify the storage capacity and evaluate this method for storing air and heat in the subsurface.

Heat dissipation during air compression has been considered an important factor in CAES energy capture efficiency, so researchers will evaluate the captured heat that is stored in the porous reservoirs with the compressed air, while determining other factors such as air speeds and the volume of formation water. The project team will also determine how much of the injected air remains in the formation during the recovery period.

“CAES has been geographically limited to areas with caverns created from subsurface salt deposits,” said Hannes Leetaru, ISGS geologist and principal investigator of the project. “However, the Illinois CAES project will evaluate using subsurface porous reservoirs without the need for caverns by injecting compressed air into subsurface porous strata. This is the first ever subsurface porous reservoir CAES system that is being attempted.”

Underground and above-ground hydrogen storage

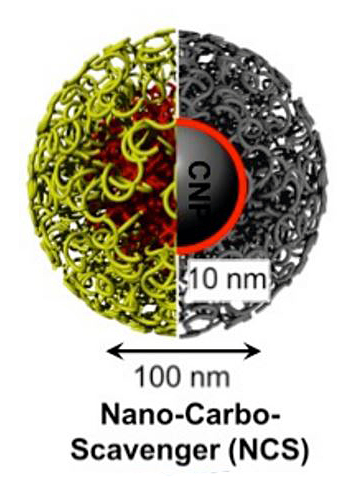

Scientists at the Illinois State Geological Survey (ISGS) will team with several companies on a $200,000 DOE-funded project to study the feasibility of storing hydrogen underground in sedimentary rock, by determining baseline subsurface requirements and conditions for hydrogen storage. An above-ground compressed hydrogen storage system will also be used for a combined storage of more than 250 megawatt hours.

The hydrogen will be produced from natural gas by the Gas Technology Institute’s novel compact hydrogen generator. This process also produces carbon dioxide that will be captured and sequestered geologically.

Some of the hydrogen will be stored on the surface for immediate demand use and some will be stored underground separately from the carbon dioxide for longer duration energy storage. The combination of generating hydrogen for energy coupled with storage of carbon dioxide is considered “blue hydrogen” and results in a very low carbon emission energy source.

“The integrated energy system will also provide the means to further test and perfect the technological components to store energy underground and reduce carbon emissions,” said Steve Whittaker, ISGS geologist. “Successful integration of this approach will significantly increase opportunities for hydrogen storage across the U.S. as well as transform energy sustainability options by the tandem sequestration of CO2.”

Partners on the project include the Gas Technology Institute, Mitsubishi Heavy Industries, Hexagon Purus, and Ameren. DOE provided $200,000 in funding for the $316,000 project.

—-

Media contacts: Kevin OBrien, kcobrien@illinois.edu; Hannes Leetaru, hleetaru@illinois.edu; Steve Whittaker, sgwhit@illinois.edu

news@prairie.illinois.edu

This post originally appeared at Prairie Research Institute News. Read the original post.