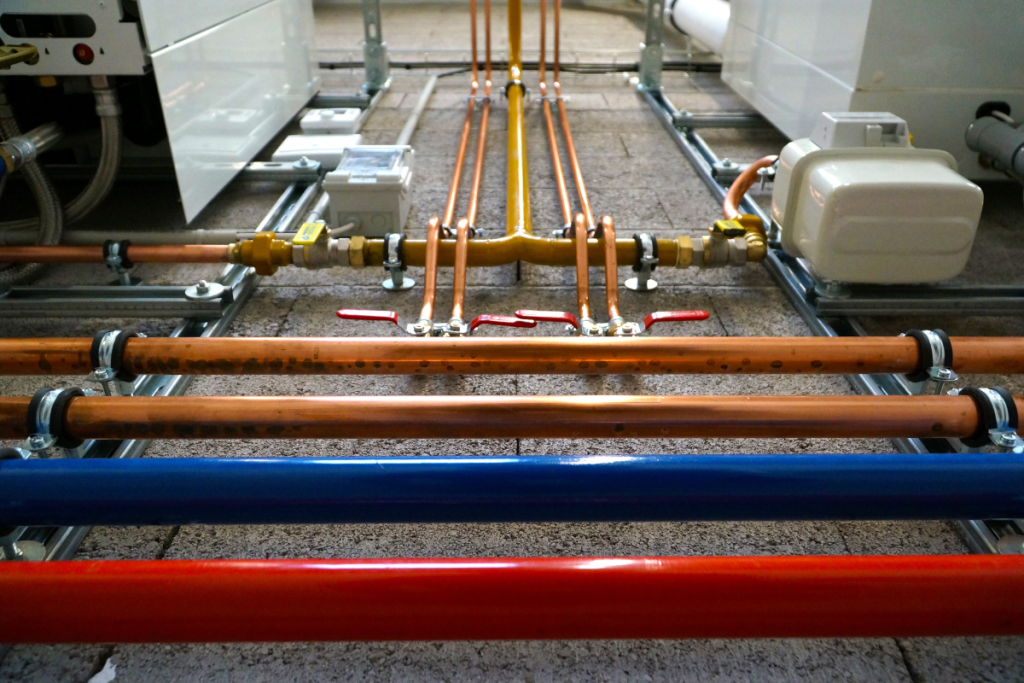

Part of the Illinois Sustainable Technology Center’s Technical Assistance Program (TAP), the Institutional Water Treatment program, or IWT, provides unbiased, professional water treatment advice to facilities equipped with institutional water systems such as cooling towers, chillers, boilers, etc. IWT services support public health and safety while also facilitating cost savings associated with chemicals, energy, water, and maintenance in industrial and potable water systems. Services range from presenting on-site training and seminars to providing chemical specifications and making recommendations concerning a comprehensive water treatment program for the control of corrosion, mineral scale formation, and biological growth.

Recently, IWT has added to its list of valuable services by offering testing for Legionella pneumophila, the bacterium that causes Legionnaires’ disease–a potentially fatal type of pneumonia (lung infection). L. pneumophila also causes Pontiac fever, a less serious, flu-like illness. This bacterium can grow in building water systems, such as showerheads, sink faucets, cooling towers, ice machines, spa pools, evaporative condensers, hot water systems, and complex plumbing systems. People become infected by inhaling tiny water droplets containing bacteria, or by aspirating contaminated drinking water (accidentally inhaling water into the lungs or windpipe when drinking).

Legionnaires’ disease and L. pneumophila derive their names from a 1976 outbreak of pneumonia that occurred among attendees of an American Legion convention at the Bellevue-Stratford Hotel in Philadelphia, PA. There were a total of 182 reported cases, with 29 deaths, among the 2000 attendees. The cause of the outbreak was eventually determined to be a previously unknown bacterium, L. pneumophila, which had bred within the cooling tower of the hotel’s air conditioning system and subsequently spread throughout the building, infecting the Legionnaires. Once this bacterium had been isolated, the Centers for Disease Control (CDC) were able to retroactively attribute earlier outbreaks of disease to it, including earlier cases of Legionnaires’ and an outbreak of a flu-like illness at a health department in Pontiac, MI which became known as Pontiac fever.

According to the CDC, health departments reported nearly 10,000 cases of Legionnaires’ disease in the United States in 2018; however, Legionnaires’ disease is likely underdiagnosed, so this may underestimate the true incidence. Since no vaccines exist to prevent Legionnaires’ disease, the key to prevention is proper maintenance of building water systems to reduce the risk of growth and spread of bacteria. Regular maintenance testing of large distribution water systems provides validation that the water management program is effectively preventing the growth of L. pneumophila. Testing is also performed during outbreak investigations to identify the source of bacteria where reported cases of Legionnaires’ disease have been confirmed.

IWT offers on-site water sample collection and two laboratory test methods for L. pneumophila detection. The IWT laboratory is one of only six laboratories in Illinois that is CDC ELITE Certified for Legionella testing. The CDC Environmental Legionella Isolation Techniques Evaluation (ELITE) is a yearly program where laboratories demonstrate their proficiency in successfully identifying Legionella in water samples.

If you’re interested in exploring IWT’s testing service for your facility, you can download a flyer on the L. pneumophila testing service, visit the TAP web site, or contact Don Kueneke via email or phone at 217-333-3659.