Visitors from the U.S. Department of Energy National Energy Technology Laboratory (DOE-NETL) recently toured multiple carbon capture projects led by the Illinois Sustainable Technology Center (ISTC).

Because the unique geology of Illinois provides extensive potential to store carbon dioxide deep underground, the state is also an ideal location to develop, demonstrate, and deploy technologies to capture CO2 from point sources, remove CO2 from the ambient air, and beneficially use CO2. ISTC scientists and engineers lead a number of carbon capture, removal, and use projects backed by funding from the Department of Energy.

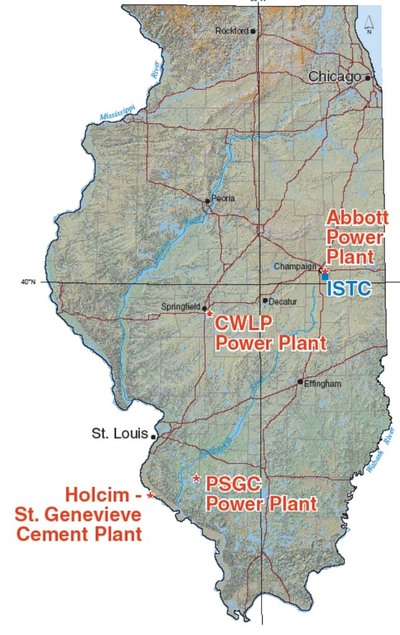

The tour included carbon capture projects at Abbott Power Plant at the University of Illinois Urbana-Champaign; City Water, Light & Power in Springfield, Prairie State Generating Company in Marissa, Illinois; and the Ste. Genevieve Cement Plant in Missouri.

Abbott Power Plant

The University’s Abbott Power Plant , a cogeneration facility that simultaneously produces both steam and electricity to meet 70-75% of the Urbana campus’s energy needs, is a partner on two ISTC-led carbon capture projects.

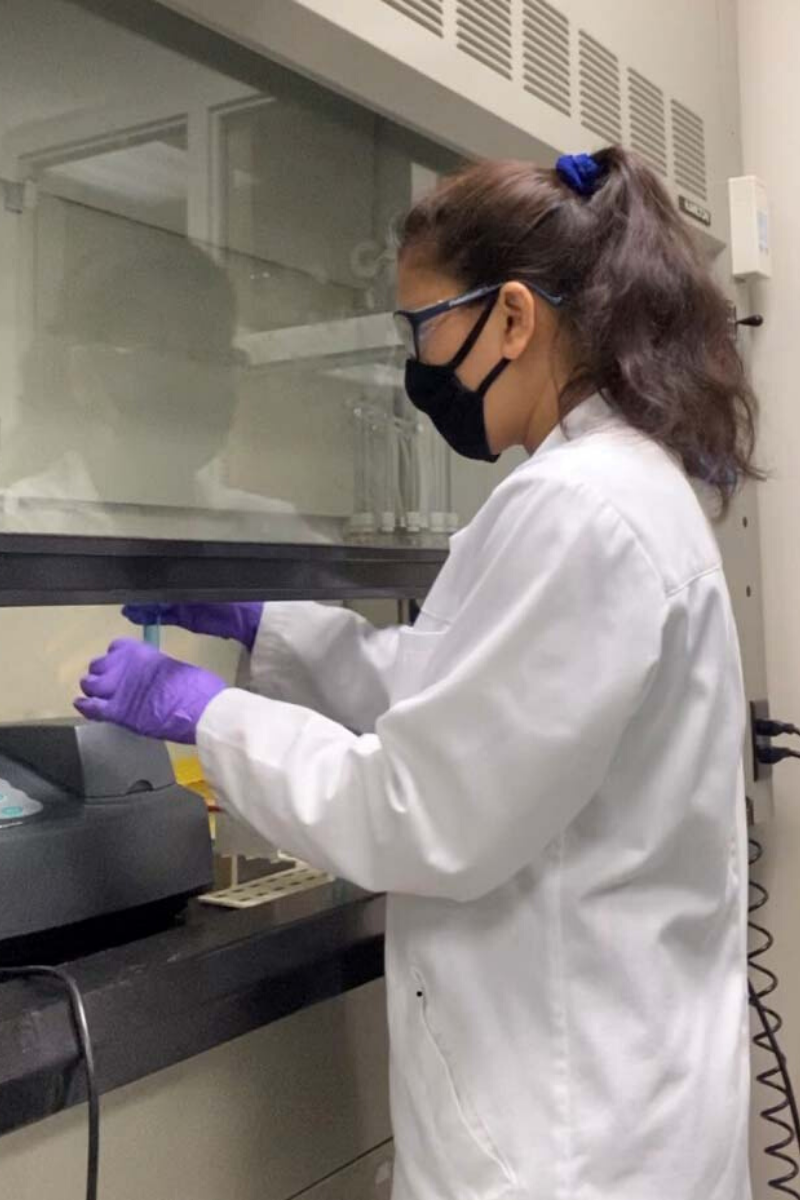

ISTC led a project, supported by $3.4 million from DOE-NETL, to evaluate an innovative biphasic solvent system for its efficiency and effectiveness in absorbing CO₂ from flue gas at Abbott. The system was designed based on the testing results at the laboratory scale under a previous DOE cooperative agreement. Read more about the biphasic solvent system.

A second project is based on a mixed-salt carbon capture technology developed by SRI International. This technology is being tested at engineering scale at Abbott in a 0.5 megawatt electric (MWe) equivalent pilot campaign. This project is supported by a grant of more than $18 million from DOE-NETL. Read more about the mixed-salt capture technology.

City Water, Light & Power

ISTC leads the large-scale pilot testing of a Linde-BASF CO2 solvent-based carbon capture technology at City Water, Light & Power (CWLP) in Springfield, Illinois. When the 10-megawatt capture system is built and begins to process 5 percent of the Dallman Unit 4 flue gas, it will capture more than 90 percent of those CO2 emissions. DOE has provided $47 million for this build-operate project, and the State of Illinois has pledged an additional $20 million. Read more about the large pilot project at CWLP.

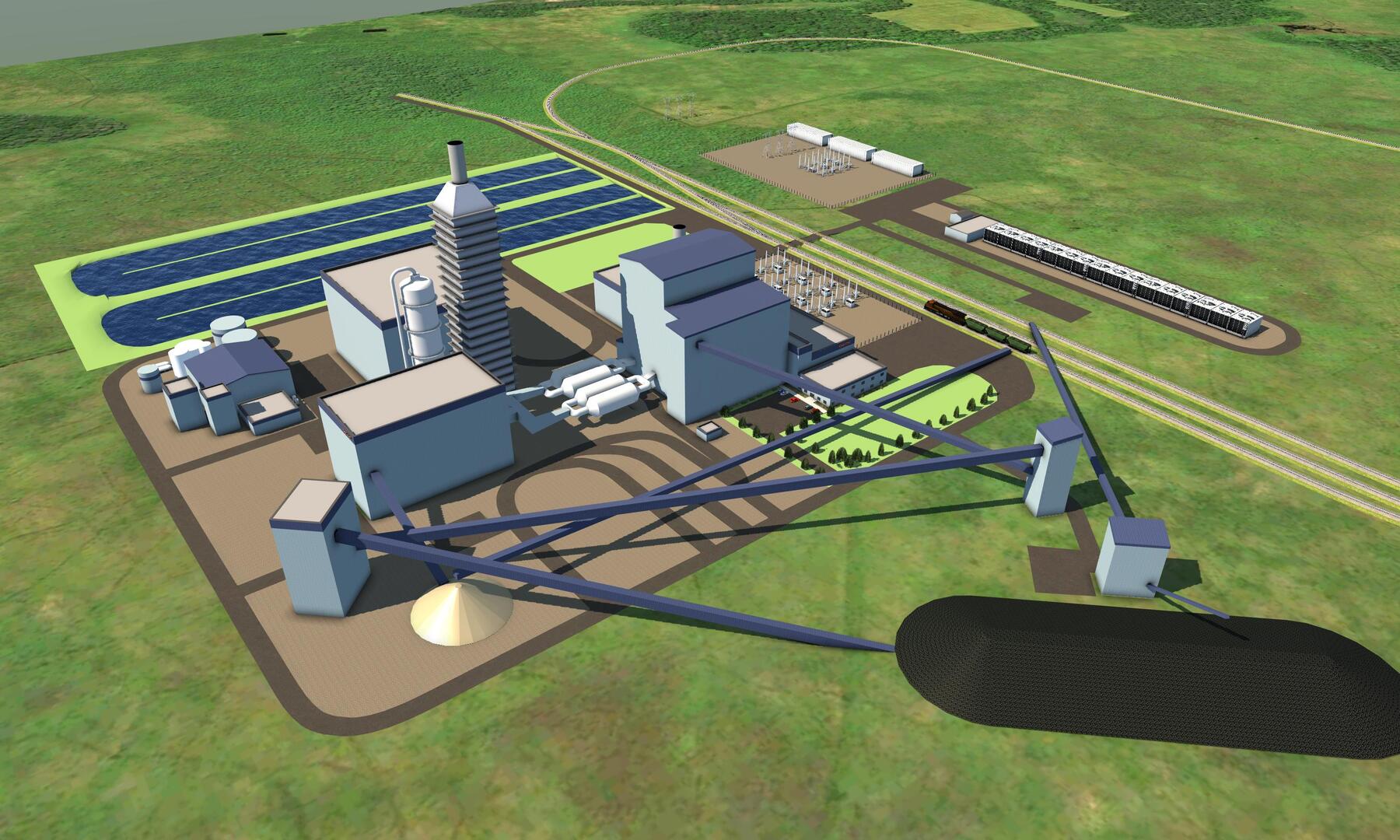

A second project led by ISTC and backed by $25 million from DOE aims to design a next-generation power plant at CWLP that both reduces emissions and captures and uses carbon dioxide. The design combines a 270-megawatt ultra-supercritical coal boiler, an 87-megawatt natural gas combustion turbine generator, a 50-megawatt energy storage subsystem, and a post-combustion carbon capture subsystem. Read more about the next-generation power plant project.

ISTC is investigating the use of CO2 captured from CWLP, as well as nutrients from wastewater treatment plants to grow algae. The cultivated high-protein Spirulina can be used in animal feeds. This engineering-scale algae project is supported by $2.5 million from DOE. Read more about the algae project.

Prairie State Generating Company

ISTC leads a front-end engineering design (FEED) study to retrofit the Prairie State Generating Company (PSGC) in Marissa, Illinois, with a solvent-based post-combustion carbon capture technology from Mitsubishi Heavy Industries. At 816 megawatts, this is the largest carbon capture FEED study in the world, with a system projected to be capable of capturing 8.5 million tonnes of CO2 each year. Read more about the FEED study at Prairie State Generating Company.

Ste. Genevieve Cement Plant

Cement is a ubiquitous construction material, and its production produces tonnes of carbon dioxide each year. While scientists are working on alternative cements and lower-carbon production processes, it is likely that capturing and either using or storing emissions from cement production will be necessary to meet carbon reduction targets.

ISTC leads a front-end engineering and design (FEED) study for a commercial-scale carbon capture retrofit of Holcim’s Ste. Genevieve Cement Plant in Bloomsdale, Missouri. The project focuses on Air Liquide’s CrycocapTM FG system for carbon capture and is backed by $4 million from DOE-NETL. Read more about the Ste. Genevieve carbon capture project.

Carbon removal through direct air capture

Projects to remove carbon dioxide from ambient air, called direct air capture (DAC), were not included in the recent tour but are a growing part of ISTC’s carbon management portfolio.

ISTC leads a project, backed by a grant of nearly $2.5 million from DOE-NETL, to develop preliminary designs and determine feasibility for the first commercial-scale direct air capture and storage system (DAC+S) for CO2 removal in the United States. This 18-month project will explore the possibility of pulling 100,000 tonnes of CO2 from the air annually, using technology from the Swiss company Climeworks, which has built and operated several DAC plants in various climates across Europe. The ISTC-led team will test the large-scale DAC systems at three sites across the U.S. in order to assess how different climate conditions impact the process. Read more about the DAC+S project.

ISTC and Climeworks also are collaborating on a $2.5 million FEED study of a DAC system to capture CO2 for underground storage. The California host site, a geothermal plant, will provide thermal energy to drive the DAC process; the site also is close to a proposed geological storage facility in the Joaquin Basin.

ISTC also leads a FEED study of direct air capture technology developed by CarbonCapture Inc. at U. S. Steel’s Gary Works Plant in Gary, Indiana. This project incorporates use of the captured carbon dioxide at a nearby Ozinga ready mix concrete plant. Injecting the CO2 into the concrete as it is being mixed causes the CO2 to mineralize, locking it in the concrete and preventing it from returning to the atmosphere. By using the U. S. Steel plant’s waste heat, energy needs can be reduced. Read more about the carbon capture and use FEED study at U. S. Steel’s Gary Works Plant.

Finally, ISTC is a partner on a project that is exploring the benefits of constructing DAC technology at Constellation Energy’s Byron nuclear energy plant in Northern Illinois. Although nuclear plants do not produce carbon emissions, the plant can provide energy to power the DAC system, which could capture 250,000 tons of CO2 each year.

Read more about sustainable energy research and development at the Prairie Research Institute.